Tag: composites

-

Digital Structures heads to World Maker Faire in NYC2015-09-25, Tags: fabrication 3d-printing additive-manufacturing mars composites

Digital Structures heads to World Maker Faire in NYC2015-09-25, Tags: fabrication 3d-printing additive-manufacturing mars compositesMitchell Gu, Caitlin Mueller, and team head to NYC as finalists in the NASA 3D Printed Habitat Challenge at the World Maker Faire. Our submission includes a 3D-printed model that makes use of four different additive manufacturing strategies, including a heat-formed thermoplastic composite shell.

-

Ouroboros: 3D-Printed Martian HabitatDesign, 2015

Ouroboros: 3D-Printed Martian HabitatDesign, 2015Ouroboros is an additive manufacturing and spatial concept for producing architectural-scale composite structures that are high-strength, light-weight, and air-tight—all from compounds present on Mars. A shared symbol of ancient cultures, the ouroboros is the idealized embodiment of metabolism; an infinite process of re-creation, of something beginning anew as soon as it ends. Today, the aspiration of the ouroboros persists as we seek to initiate a new and sustainable human culture of technology and design on Mars.

The Ouroboros habitat promotes a metabolic rhythm of activity reflective of its circular geometry and processing of materials. The proposed materials processing unit, 3D CNC loom, and pultrusion module apply emerging technologies to synthesize a pressurized and climate controlled living space from Martian resources. Martian soil and air are processed and transformed into glass and plastic fibers that can be woven and pultruded into a strong, airtight composite shell; integrating structure, insulation, air barrier, radiant heating, and ambient lighting, within a singular structural surface. Using a new approach for the additive manufacturing of structural composites, a CNC loom forms the thermoset textiles into a global toroidal shape by combining pultrusion with three-dimensional textile weaving. Structurally, the lightweight tensile shell of the habitat takes full advantage of the reduced Martian pressure and gravity, allowing for minimal material usage and maximal reconfigurability of the interior. Contributing novel approaches to structure, material selection, programmatic flexibility, and spatial experience, Ouroboros represents a revolution in current thinking in sustainable, architectural-scale additive manufacturing and design on Mars and beyond.

This design project is a submission for NASA's 3D-Printed Habitat Challenge, and was selected as a finalist to be presented at the NYC Maker Faire in late September 2015. More information and details about our proposal can be found here, and a gallery of all finalists is here.

-

Digital Structures Finalists in NASA's 3D-Printed Habitat Challenge2015-09-01, Tags: fabrication additive-manufacturing space-architecture mars composites

Digital Structures Finalists in NASA's 3D-Printed Habitat Challenge2015-09-01, Tags: fabrication additive-manufacturing space-architecture mars compositesAn interdisciplinary team of Digital Structures students, along with Justin Lavallee of the Architecture Fab Lab, are finalists in a NASA competition to design 3D-printed habitats for a 2035 Mars mission. Our submision will be presented at the World Maker Faire in New York on Sept. 26-27. More information about our design concept, called Ouroboros, and fabrication processes can be found here.

-

Forces Frozen: Exploring Structural Ice ShellsWorkshop, 2014 - Present

Forces Frozen: Exploring Structural Ice ShellsWorkshop, 2014 - PresentTaught each year in January during MIT's Independent Activities Period (IAP), this weeklong workshop explores the world of structural ice shells, inspired by Swiss engineer and designer Heinz Isler (1926-2009). The course begins by researching ice/fabric forms and the methods for making them, and in the following days, students explore and design their own ice-fabric structures, along with building formwork and rigging systems. On the final day, the group constructs a landscape of frozen structures on the MIT campus and shares the work with friends and colleagues. For more images and information about the workshop, see the this Tumblr page and this video, which was featured on the MIT homepage in January 2015 (taught with Corentin Fivet).

Since 2015, the workshop has been sponsored by the MIT-SUTD Collaboration Office, and involves students from MIT and the Singapore University of Technologiy and Design. In January 2016, the workshop was taught by Caitlin Mueller and Lancelot Coar, Assistant Professor at the University of Manitoba and world expert in ice shell design and construction.

-

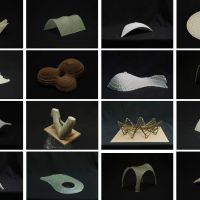

4.154: Un-flat Options StudioClass, 2015

4.154: Un-flat Options StudioClass, 2015Taught with Joel Lamere in Spring 2015, this options-level architectural design studio is part of the cross-studio initiative, a new program to develop studios that connect design with other disciplines. Called Un-flat Inevitabilities: Integrated Form and Structure in the Age of Simulation and Composites, the studio focuses on possibilities and frictions at the interface of architectural geometry and structural performance, as facilitated by contemporary computational tools and processes that integrate structural thinking and design intent. The extended studio brief is as follows:

Architecture’s enduring preoccupation with structure as a formal alibi has evolved alongside the tools we use to define and evaluate geometries. The fidelity between structurally-informed shape and architectural object is continually constrained to representable forms, calculable structural behaviors and other short-hand abstractions that simulate how objects will act and react once materialized. The history of architectural structures revels in this abstraction; Gaudi’s hanging-chain models reduce structure to the funicular, Nervi’s flow lines literalize graphic notation, Candela’s hypars exploit a coincidence between pure geometries and known equations.

We are only now beginning to graduate from a long period of computational infancy in architecture. New modeling tools, static and parametric, free architectural geometry from the representational limitations of the past. Computer-aided and digital fabrication processes are increasingly commonplace and potentially liberating. Simultaneously, the material palette available to architecture is expanding, with composites leading the way toward an eroding set of formal constraints. But most importantly to us, computational tools are emerging that promise to embed sophisticated structural behaviors into the design process. Through these, the necessary abstractions of previous generations can be replaced by simulative environments that allow a convergence of formal ambition and structural logics. This convergence allows us to imagine and construct an expanded set of possible forms, each deeply reflecting real-world material behaviors.

Yet the contingencies of architecture, the other criteria around which it must operate, resist the purity of this exercise. Take, for instance, the perfect beam, one for which efficiency is the only criteria: curved along the top and bottom with an ever-changing cross section reflecting various performative changes along its length. But as soon as you need to occupy the top of this beam one side becomes flat, and as soon as you need to make it the cross section stabilizes; a beam is inherently inefficient. This slippage -- between structural efficiency and other architectural demands -- is the most fertile ground for this new computational moment. Integrated processes and new simulative environments can embrace this call for flatness, while tapping into the un-flat inevitabilities of structural form.

The studio included a one-week trip to Mexico City to study the thin-shell concrete structures of architect-engineer Felix Candela, which inspired and contextualized many of the studio's themes.