Tag: principal-stress-lines

-

Mark Tam and Caitlin Mueller present at RobArch 2016 in Sydney2016-03-18, Tags: fabrication 3d-printing additive-manufacturing principal-stress-lines

Mark Tam and Caitlin Mueller present at RobArch 2016 in Sydney2016-03-18, Tags: fabrication 3d-printing additive-manufacturing principal-stress-linesDigital Structures are at the 3rd Robotics in Architecture conference in Sydney, Australia to share their work on robotics-enabled stress line additive manufacturing, a new 3D printing technique that deposits material along lines of force flow for enhanced structural performance.

-

Digital Structures presents work at ACADIA 2015 in Cincinnati2015-10-27, Tags: computation principal-stress-lines

Digital Structures presents work at ACADIA 2015 in Cincinnati2015-10-27, Tags: computation principal-stress-linesCaitlin Mueller attended the 2015 ACADIA conference to share her and Mark Tam's work on generating materializable stress lines for architectural design.

-

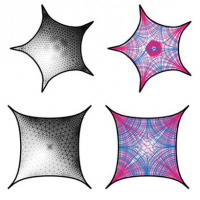

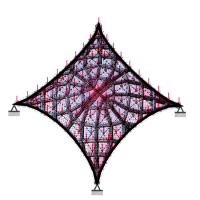

Principal stress line computation for discrete topology designKam-Ming Mark Tam, MIT MEng Thesis, 2015

Principal stress line computation for discrete topology designKam-Ming Mark Tam, MIT MEng Thesis, 2015Principal stress lines, which are pairs of orthogonal curves that indicate trajectories of internal forces and therefore idealized paths of material continuity, naturally encode the optimal topology for any structure for a given set of boundary conditions. Although stress line analysis has the potential to offer a direct, and geometrically provocative approach to optimization that can synthesize both design and structural objectives, its application in design has generally been limited due to the lack of standardization and parameterization of the process for generating and interpreting stress lines. Addressing these barriers that limit the application of the stress line methods, this thesis proposes a new implementation framework that will enable designers to take advantage of stress line analysis to inform conceptual structural design. Central to the premise of this research is a new conception of structurally inspired design exploration that does not impose a singular solution, but instead allows for the exploration of a diverse high-performance design space in order to balance the combination of structural and architectural design objectives. Specifically, the thesis has immediate application for the topological design of both regular and irregular thin shell structures predominately subjected to in-plane and compressive structural actions.

-

Stress line computation for structurally performative topologyResearch, 2014 - 2015

Stress line computation for structurally performative topologyResearch, 2014 - 2015Principal stress lines, which are pairs of orthogonal curves that indicate trajectories of internal forces and therefore idealized paths of material continuity, naturally encode the optimal topology for any structure for a given set of boundary conditions. Although stress line analysis has the potential to offer a direct, and geometrically provocative approach to optimization that can synthesize both design and structural objectives, its application in design has generally been limited due to the lack of standardization and parameterization of the process for generating and interpreting stress lines. Addressing these barriers that limit the application of the stress line methods, this project proposes a new implementation framework that will enable designers to take advantage of stress line analysis to inform conceptual structural design.

-

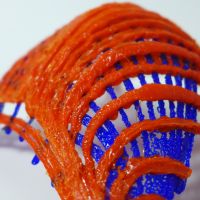

Stress line additive manufacturing (SLAM)Research, 2014 - 2015

Stress line additive manufacturing (SLAM)Research, 2014 - 2015The project presents a new integrated software and hardware process that reconsiders the traditional addive manufacturing (AM) technique of fused deposition modelling (FDM) by adding material explicitly along the three-dimensional principal stress trajectories, or stress lines, of 2.5-D structural surfaces. Using a six-axis robotic arm, this project materializes continuous stress fields into discrete structural topologies, rendered computationally as robotic tool paths. The goal of this project is to develop and perfect this new technique, and to explore conditions in which it is favorable to conventional layer-based additive manufacturing. The research is supported by methodologies including computational structural analysis and comparative structural load testing. For more video information, see this YouTube video.

-

Stress line additive manufacturing (SLAM) for 2.5-D shellsKam-Ming Mark Tam, Caitlin Mueller, James Coleman, and Nicholas Fine, Proceedings of the International Association for Shell and Spatial Structures (IASS) Symposium 2015, 2015

Stress line additive manufacturing (SLAM) for 2.5-D shellsKam-Ming Mark Tam, Caitlin Mueller, James Coleman, and Nicholas Fine, Proceedings of the International Association for Shell and Spatial Structures (IASS) Symposium 2015, 2015In the field of digital fabrication, additive manufacturing (AM, sometimes called 3D printing) has enabled the fabrication of increasingly complex geometries, though the potential of this technology to convey both geometry and structural performance remains unmet. Typical AM processes produce anisotropic products with strength behavior that varies according to filament orientation, thereby limiting its applications in both structural prototypes and end-use parts and products. The paper presents a new integrated software and hardware process that reconsiders the traditional AM technique of fused deposition modelling (FDM) by adding material explicitly along the threedimensional principal stress trajectories, or stress lines, of 2.5-D structural surfaces. As curves that indicate paths of desired material continuity within a structure, stress lines encode the optimal topology of a structure for a given set of design boundary conditions. The use of a 6-axis industrial robot arm and a heated extruder, designed specifically for this research, provides an alternative to traditional layered manufacturing by allowing for oriented material deposition. The presented research opens new possibilities for structurally performative fabrication.

-

Stress line generation for structurally performative architectural designKam-Ming Mark Tam and Caitlin Mueller, Computational Ecologies: Proceedings of the 35th Annual Conference of the Association for Computer Aided Design in Architecture, 2015

Stress line generation for structurally performative architectural designKam-Ming Mark Tam and Caitlin Mueller, Computational Ecologies: Proceedings of the 35th Annual Conference of the Association for Computer Aided Design in Architecture, 2015Principal stress lines, which are pairs of orthogonal curves that indicate trajectories of internal forces and therefore idealized paths of material continuity, naturally encode the optimal topology for any structure for a given set of boundary conditions. Although stress line analysis has the potential to offer a direct, and geometrically provocative approach to optimization that can synthesize both design and structural objectives, its application in design has generally been limited due to the lack of standardization and parameterization of the process for generating and interpreting stress lines. Addressing these barriers that limit the application of the stress line methods, this paper proposes a new implementation framework that will enable designers to take advantage of stress line analysis to inform conceptual structural design. Central to the premise of this research is a new conception of structurally inspired design exploration that does not impose a singular solution, but instead allows for the exploration of a diverse high-performancedesign space in order to balance the combination of structural and architectural design objectives.