Tag: robotic-fabrication

-

Automated sequence and motion planning for robotic spatial extrusion of 3D trussesYijiang Huang, Caelan R. Garrett and Caitlin T. Mueller, Preprint, arXiv:1810.00998, 2018

Automated sequence and motion planning for robotic spatial extrusion of 3D trussesYijiang Huang, Caelan R. Garrett and Caitlin T. Mueller, Preprint, arXiv:1810.00998, 2018While robotics for architectural-scale construction has made significant progress in recent years, a major challenge remains in automatically planning robotic motion for the assembly of complex structures. This paper proposes a new hierarchical planning framework to solve the assembly planning problem for architectural discrete structures, which usually have a long planning horizon and 3D configuration complexity. By decoupling sequence and motion planning, the planning framework is able to efficiently solve the assembly sequence, end-effector poses, joint configurations, and transition trajectories for assembly of spatial structures with nonstandard topologies, which hasn't been demonstrated in previous literature. Together with the algorithmic results, this paper also presents an open-source and modularized software implementation called Choreo that is machine and application-agnostic. To demonstrate the power of this algorithmic framework, three case studies, including real fabrication and simulation results, are presented to show Choreo's application on spatial extrusion.

-

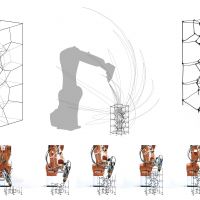

3D truss topology optimization for automated robotic spatial extrusionYijiang Huang, Josephine V. Carstensen, Caitlin T. Mueller, International Association for Shell and Spatial Structures (IASS), 2018

3D truss topology optimization for automated robotic spatial extrusionYijiang Huang, Josephine V. Carstensen, Caitlin T. Mueller, International Association for Shell and Spatial Structures (IASS), 2018This paper contributes new knowledge and results to the fields of topology optimization and robotic spatial extrusion through the consideration of how these methods can be used together. Specifically, a new topology optimization formulation is presented that accounts for the manufacturing constraints of uniform cross section and average member length. In addition, a new robotic assembly planning framework is demonstrated, which allows the complex but structurally efficient results of the topology optimization to be materialized in a reasonable amount of time. Three novel case studies produced by the proposed topology optimization framework are presented to demonstrate how automated assembly planning and robotic extrusion can enable a direct and efficient means to materialize a 3D topology-optimized truss.

-

Robotic extrusion of architectural structures with nonstandard topologyYijiang Huang, Josephine Carstensen, Lavender Tessmer and Caitlin Mueller, ROB|ARCH 2018: Robotic Fabrication In Architecture, Art and Design 2018, 2018 (Under review)

Robotic extrusion of architectural structures with nonstandard topologyYijiang Huang, Josephine Carstensen, Lavender Tessmer and Caitlin Mueller, ROB|ARCH 2018: Robotic Fabrication In Architecture, Art and Design 2018, 2018 (Under review)This paper presents a fast and flexible method for robotic extrusion (or spatial 3D printing) of designs made of linear elements that are connected in non-standard, irregular, and complex topologies. Nonstandard topology has considerable potential in design, both for visual effect and material efficiency, but usually presents serious challenges for robotic assembly since repeating motions cannot be used. Powered by a new automatic motion planning framework called Choreo, this paper’s robotic extrusion process avoids human intervention for steps that are typically arduous and tedious in architectural robotics projects. Specifically, the assembly sequence, end effector pose, joint configuration, and transition trajectory are all generated automatically using state-of-the-art, open-source planning algorithms developed in the broader robotics community. Three case studies with topologies produced by structural optimization and generative design techniques are presented to demonstrate the potential of this approach.

-

Yijiang Huang presented a poster at New England Symposium on Graphics2018-04-29, Tags: fabrication additive-manufacturing robotic-fabrication

Yijiang Huang presented a poster at New England Symposium on Graphics2018-04-29, Tags: fabrication additive-manufacturing robotic-fabricationYijiang Huang is presenting the Choreo robotic assembly planning platform at the New England Symposium on Graphics, at MIT's Stata Center on April 29, 2018.

-

Computational tools and experimental making in timber construction: In conversation with Christopher Robeller2017-11-03, Authors: Demi Fang Paul Mayencourt

Computational tools and experimental making in timber construction: In conversation with Christopher Robeller2017-11-03, Authors: Demi Fang Paul MayencourtOf the many exciting innovations in digital fabrication permeating architecture research today, the work of Christopher Robeller stands out in the growing field of timber construction. Robeller completed his PhD in 2015 on the integral mechanical attachment of timber panels at Ecole Polytechnique Federale de Lausanne (EPFL)’s laboratory for timber construction, IBOIS. He spent the following two years as a post-doctoral researcher at the Swiss National Centre in Research (NCCR), applying his research to the construction of a fully functioning building: the Vidy Theatre. Recently appointed Junior Professor in Digital Timber Construction at TU Kaiserslautern, Robeller presented his process and experience working on the Vidy at the ACADIA 2017 conference at MIT in early November of this year.

Robeller also stopped by to chat with us about his work and his thoughts on wood, the built environment, and the importance of experimentation in making. The questions and responses below have been edited for clarity.

Digital Structures: How did you get to be interested in and involved with wood?

Christopher Robeller: My family has been working with timber for a couple of generations, but for more pragmatic things like making windows. My fascination from childhood was always that wood was a nice material to work with - it’s not too dirty, and it’s something you can craft. It’s even got a nice smell to it! It’s a material I’m very passionate about.

DS: Can you describe your training in architecture and/or engineering?

CR: I studied architecture at the London Metropolitan University. It was not a mixed course, but I was always very interested in engineering at the same time. I was very impressed by all of the creativity and ideas being generated in architecture school, but there was a point where I realized that in order to make it really work, you have to overcome a lot of engineering challenges, and only if you really manage that can you make really great architecture.

I have combined my interests in architecture and engineering in the last few years. I first worked with Achim Menges, through which I collaborated a bit with Jan Knippers’s laboratory, a team of mostly engineers. When I went to IBOIS at EPFL for my PhD, I found that I was one of the few architects - there were times when I was one of two architects on a ten-person team.

It would be a shame for a building to have a strong and interesting architectural concept but have details that don’t match the quality of the rest of the building. I found an opportunity through the PhD to focus on those more in-depth aspects of geometry, fabrication, and engineering.

DS: What are your thoughts on relationship between architecture and engineering?

CR: In my traditional experience in architecture, there is not much interaction. You expect the engineer to figure it out, and most projects rely on the state-of-the-art. Architects and engineers get to work much more closely together in more experimental projects in academia.

Computational tools offer a chance for architects and engineers to work together. These tools offer control over design, and that control is valuable in both fields. There is only so much you can do with a software that comes off the shelf that was developed for certain purpose; if you want to use the software for a different purpose, you have to modify the software to make it do what you want it to do. Architects and engineers are starting to take advantage of this.

This area is where the two fields reach a bit of a common language. I am seeing computer scientists, civil engineers, and architects work on similar collaborative models. You might find a very interesting solution for your architectural or engineering problem in some algorithm that has just been developed by some computer scientists. Then you can get together and plug in together if you’re working on a common ground such as a common programming language.

DS: What are your thoughts on the relationship between academia and practice?

CR: They can be worlds apart, especially in timber construction. The community of timber construction is highly skilled but can sometimes be rather conservative. On the other hand, there is the creative and artistic community of architects who design amazing things with timber. It’s really interesting how you have to find a balance between these two groups because they can be very far from each other.

Given the complexity of wood, you have to bring the two groups together. You have to talk to the companies in the construction industry that specialize in timber. In design and engineering, we are usually generalists working with many materials, whereas these companies have long ago specialized in one material and have gained a lot of knowledge over the decades. That’s something that should be respected. If you get in touch with them - which you only do through these experimental projects - you learn a lot from them.

There is a lot of discussion right now over the social component of digitalization. There is a danger of neglecting people who are not in the loop. Once again, computational tools allow you to integrate people in industry into the design process. I think we’ve done that with the Vidy Theatre: we went to companies, talked to the experts there, and included them in the process. I specifically developed a program that the fabricator there could use. We didn’t use software that eliminate the engineer and the fabricator from the design and manufacturing process. It’s something we should think about: how these digital workflows can incorporate specialists.

DS: Do you hope to continue bridging these fields - architecture and engineering, and research and practice - through your new professorship?

CR: I am definitely trying to bring the four worlds together. People in practice already know how to do things; they’re absolute professionals in the state-of-the-art. In teaching, the beauty is in not having that expertise yet. This lets you think about things in a completely different way, in a free and open way, and you might come up with interesting and intuitive solutions.

For example, I was making the first prototype for a timber plate shell construction project in the workshop by myself, with my hands. I was assembling the prototype on its side because intuitively it made sense to allow the weight of the elements to help with insertion. But in building design, it was being designed right-side-up as usual, and that was what was causing all the problems when we tried to put together a larger prototype. It wasn’t until we finally thought back to the first prototype that I built sideways that we realized what the problem was. I might not have had that experience if I hadn’t made that prototype myself.

Timber plate shell prototype assembled on its side. Image courtesy of Christopher Robeller.

Great architects and engineers are people who quite often have been working physically themselves making things, making prototypes and models. This very rarely happens in actual architecture-engineering design processes - it’s only in academia that a designer of a building actually goes and makes not only a representational model but a functional model of some joint or assembly - himself.

Robeller (left) chats with DS students Courtney Stephen (middle) and Paul Mayencourt (right).

DS: What is something that excites you the most about future possibilities in wood?

CR: We can do amazing things with timber in fabrication, and I think that’s the biggest development in the last ten, twenty years. If you had shown me our work on the Vidy Theatre ten years ago, I would have thought it was magic. Now having done all of it, it doesn’t really seem like magic anymore.

We have come a far way, and it’s much easier to do these things now. While geometry processing and fabrication have become more manageable, the building implementations allow us to focus on new challenges such as integrated concepts for structural engineering and building physics.

One reason I went to IBOIS is because of their machinery (5-axis CNC machine). If you want to experiment with the making of today, you need the technology to be accessible; you don’t have that everywhere. In educational institutions, it’s very important to not only have the technology but to have it accessible to the greater community.

It’s funny, I talked to companies like Blumer Lehmann - they had their first 5-axis machine in 1985. That’s how long they’ve had it! Mechanically, not much has changed. You probably could have done the Vidy Theatre back then. The computer was surely capable enough. The limitation was accessibility: you didn’t have the CNC machinery in universities, at least in architecture and engineering. CNC technology may have been developed at MIT, but it took a long time for it to come into architecture and building in a way that’s accessible to the architecture research community.

Construction of Vidy Theatre. Image courtesy of Christopher Robeller.

Another exciting challenge I see is that not only do we have something very beautiful, but we also have something that can make a positive impact in terms of the ecological construction that we need so much. It’s like having your cake and eating it too! We have something beautiful, something interesting, we can address the challenges of digitalization by making jobs more pleasant and more interesting and less hard manual work, and at the same time we can maybe make it more ecologic. But that’s really a maybe; I’m very self-critical about my work so far, and it has not been something focusing on sustainability - yet. But this is clearly something I see as a realistic possibility and something I want to look more into.

DS: Do you have any advice for young researchers and architects who are interested in exploring and applying timber innovations?

CR: Be passionate and be creative. When you first begin as a student, you’re very free from any state-of-the-art that tells you how things are supposed to work. You have to use the moment. Eventually, of course, you have to learn all of the things, but every stage of the journey is an interesting step.

-

Automatic Path Planning Framework for Robotic ConstructionResearch, 2016 - Present

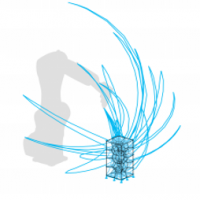

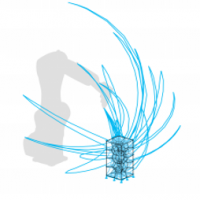

Automatic Path Planning Framework for Robotic ConstructionResearch, 2016 - PresentIn the design process for robotic construction, architects have increasingly powerful tools to help simulate and visualize robotic motion within a parametric design environment. However, these tools still require that designers manually “plan” for the robot, generating guiding curves for robot to follow that avoid collisions with objects in work environment. This significantly slows down the digital fabrication workflow and sometimes prohibits the materialization of design due to the intricate planning process.

This project introduces a new workflow that overcomes these limitations through an automated robotic path planning software layer linking design geometry to robotic toolpath code. The proposed framework takes input design from designers and automatically plan for robotic trajectories to carry out the task. The planning algorithm integrates planning constraints to ensure that collisions, robotic axis singularities, and other disruptions do not occur.

-

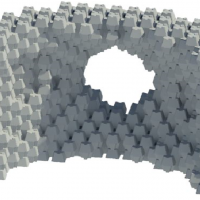

Drone-based additive manufacturing of architectural structuresResearch, 2014 - Present

Drone-based additive manufacturing of architectural structuresResearch, 2014 - PresentIn collaboration with Professor Pierre Latteur and students from Université catholique de Louvain, this project investigates new possibilities for using unmanned aerial vehicles (UAVs), commonly called drones, in the fabrication of buildings and bridges. Preliminary work in this project has focused on the development of brick-like voxels, called droxels, that can be transported and assembled into stabile and geometrically complex structures by drones. Ongoing efforts include developing and implementing a parametric software framework that turns architectural geometry into assembly sequences and ultimately drone flight paths. This collaboration is funded in part by the MISTI MIT-Belgium program.

-

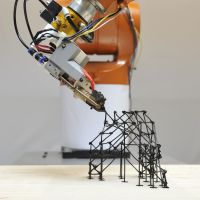

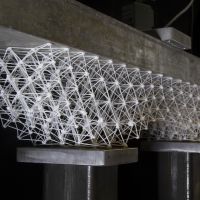

Structural lattice additive manufacturingResearch, 2015 - Present

Structural lattice additive manufacturingResearch, 2015 - PresentThe structural performance of traditional 3D-printed parts is typically limited by nature of the ayer-by-layer construction. Such parts are anisotropic due to decreased adhesion between layers and the internal structure is uniform, not flexible. This project seeks to overcome these limitations by printing along the edges of a stress-optimized lattice. With this approach, larger-scale, lightweight parts can be printed with an optimal structure that can vary depending on a loading configuration. The results of this project may be promising for diverse fields including concrete rebar design, spaceframe prototyping for buildings, and generative art.

The fabrication component of the project includes designing a custom extruder for a six-axis robotic arm that excels in printing along hard-to-reach toolpaths in free air, with larger nozzle diameters. To complement this technology, a computational tool is in development to generate lattices and toolpaths for any part and its loading configuration.

-

Robotics-enabled stress line additive manufacturingKam-Ming Mark Tam, Caitlin Mueller, James Coleman, and Nicholas Fine, Rob|Arch 2016: Robotic Fabrication in Architecture, Art and Design 2016, 2016

Robotics-enabled stress line additive manufacturingKam-Ming Mark Tam, Caitlin Mueller, James Coleman, and Nicholas Fine, Rob|Arch 2016: Robotic Fabrication in Architecture, Art and Design 2016, 2016The presented research uses a 6-axis industrial robot arm and a custom-designed heated extruder to develop a new robotic additive manufacturing (AM) framework for 2.5-D surface designs that adds material explicitly along principal stress trajectories. AM technologies, such as fused deposition modelling (FDM), are typically based on processes that lead to anisotropic products with strength behaviour that varies according to filament orientation; this limits its application in both design prototypes and end-use parts and products. Since stress lines are curves that indicate the optimal paths of material continuity for a given design boundary, the proposed stress-line based oriented material deposition opens new possibilities for structurally-performative and geometrically-complex AM, which is supported here by fabrication and structural load testing results. Called stress line additive manufacturing (SLAM), the proposed method achieves an integrated workflow that synthesizes parametric design, structural optimization, robotic computation, and fabrication.